Products Category

-

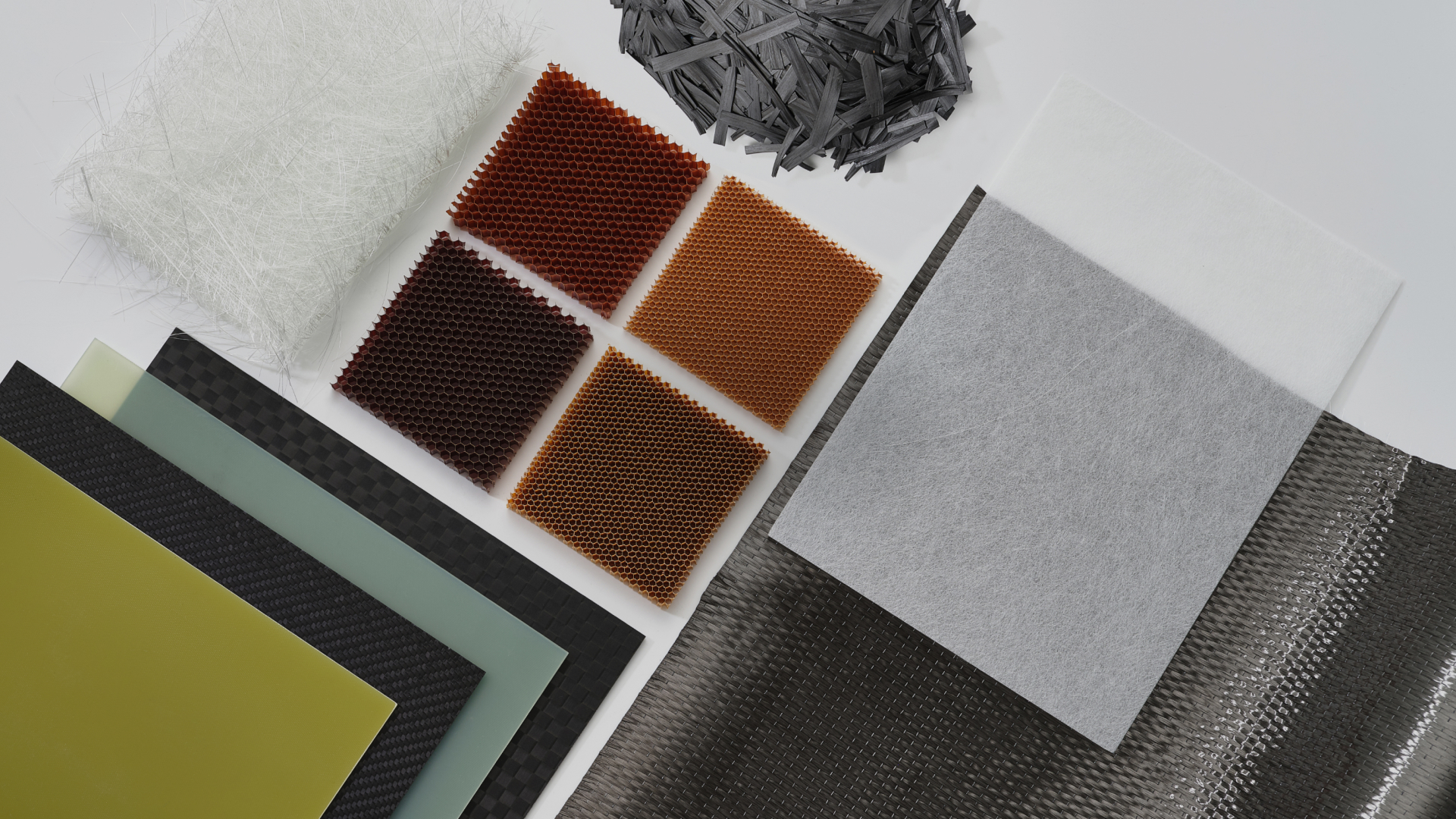

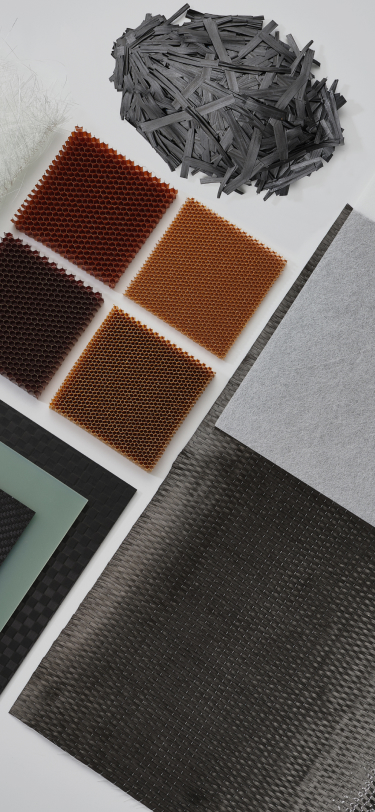

Carbon FabricFabricCarbon FabricCarbon fabric is widely recognized for its exceptional strength-to-weight ratio, tensile strength, modulus, and temperature resistance. They are extensively used in many fields as composites showing excellent function and material properties. Carbon fibers are utilized either in the natural form or coated with the appropriate type of resin, depending on the intended application.

Carbon FabricFabricCarbon FabricCarbon fabric is widely recognized for its exceptional strength-to-weight ratio, tensile strength, modulus, and temperature resistance. They are extensively used in many fields as composites showing excellent function and material properties. Carbon fibers are utilized either in the natural form or coated with the appropriate type of resin, depending on the intended application. -

Glass FabricFabricGlass FabricGlass fabric is commonly used as reinforcements in composites, with excellent tensile strength, dimensional stability, electrical insulation, heat resistance, chemical resistance, and weathering resistance. It is sold as glass fiber and also as a fabric, utilized with appropriate resin coating, depending on the intended application.

Glass FabricFabricGlass FabricGlass fabric is commonly used as reinforcements in composites, with excellent tensile strength, dimensional stability, electrical insulation, heat resistance, chemical resistance, and weathering resistance. It is sold as glass fiber and also as a fabric, utilized with appropriate resin coating, depending on the intended application. -

Hybrid FabricFabricHybrid FabricHybrid fabric is a material that combines the advantages of carbon fiber, glass fiber, and aramid fiber (Kevlar). It offers excellent strength, abrasion, and fatigue resistance, as well as a high strength-to-weight ratio and dimensional stability. It is used in various fields such as motorsports wear, aircraft construction & shipbuilding, sports equipment, automotive engineering, electrical appliances, and many other applications that require unique designs.

Hybrid FabricFabricHybrid FabricHybrid fabric is a material that combines the advantages of carbon fiber, glass fiber, and aramid fiber (Kevlar). It offers excellent strength, abrasion, and fatigue resistance, as well as a high strength-to-weight ratio and dimensional stability. It is used in various fields such as motorsports wear, aircraft construction & shipbuilding, sports equipment, automotive engineering, electrical appliances, and many other applications that require unique designs. -

UPF™FabricUPF™UPF™ (Unidirectional Prepreg Fabric) is a prepreg fabric woven from carbon fiber prepreg tape impregnated with epoxy resin. By slitting the tape to a certain width, it is possible to create a fabric with a custom design. Low-thickness fabrics can be created with various fibers, allowing for adjusting the weight of the fibers as well. Another benefit is that it saves costs as special woven fibers are not used.

UPF™FabricUPF™UPF™ (Unidirectional Prepreg Fabric) is a prepreg fabric woven from carbon fiber prepreg tape impregnated with epoxy resin. By slitting the tape to a certain width, it is possible to create a fabric with a custom design. Low-thickness fabrics can be created with various fibers, allowing for adjusting the weight of the fibers as well. Another benefit is that it saves costs as special woven fibers are not used. -

CSMFabricCSMCSM (Continuous Strand Mat) is a material mostly applied in storage tank inner materials in LNG carriers. It is usually bonded with polyurethane to compose a PU foam block, and used as a material to form the surface of the outer wall of the storage tank. CSM is known to improve the tensile strength of polyurethane foam blocks at both room temperature (23℃) and cryogenic temperature (-170℃).

CSMFabricCSMCSM (Continuous Strand Mat) is a material mostly applied in storage tank inner materials in LNG carriers. It is usually bonded with polyurethane to compose a PU foam block, and used as a material to form the surface of the outer wall of the storage tank. CSM is known to improve the tensile strength of polyurethane foam blocks at both room temperature (23℃) and cryogenic temperature (-170℃). -

Hot-MeltPrepregHot-MeltThe hot-melt method applies heat and pressure to the resin-coated release liner cast on a reinforced fiber, impregnating the melted resin into the reinforced fiber. It allows for precise manufacturing, making it ideal for high-tech applications.

Hot-MeltPrepregHot-MeltThe hot-melt method applies heat and pressure to the resin-coated release liner cast on a reinforced fiber, impregnating the melted resin into the reinforced fiber. It allows for precise manufacturing, making it ideal for high-tech applications. -

SolventPrepregSolventThe solvent method involves dissolving the epoxy resin in a solvent bath, which allows the epoxy resin and the curing agent to mix. Hankuk Carbon has developed epoxy and phenolic prepreg resin systems contributing to weight reduction, fire resistance, and durability.

SolventPrepregSolventThe solvent method involves dissolving the epoxy resin in a solvent bath, which allows the epoxy resin and the curing agent to mix. Hankuk Carbon has developed epoxy and phenolic prepreg resin systems contributing to weight reduction, fire resistance, and durability.

Our solutions are suitable for aerospace, rail and electronics, and we produce a wide range of coated products using thermosetting and thermoplastic resin. -

Glass PaperPaperGlass PaperGlass paper consists of continuous glass fibers cut to a specific length, produced through a wet-laid technique. Due to its excellent properties, such as dimensional stability, it is widely used in various industries, including building materials and composites. By combining organic, inorganic, and natural fibers, glass paper has become the primary material for sheet and tile flooring and insulation and is supplied to building material manufacturers worldwide.

Glass PaperPaperGlass PaperGlass paper consists of continuous glass fibers cut to a specific length, produced through a wet-laid technique. Due to its excellent properties, such as dimensional stability, it is widely used in various industries, including building materials and composites. By combining organic, inorganic, and natural fibers, glass paper has become the primary material for sheet and tile flooring and insulation and is supplied to building material manufacturers worldwide. -

Carbon PaperPaperCarbon PaperCarbon paper consists of carbon fibers cut to a specific length, produced through a wet-laid technique. Due to its excellent properties, such as dimensional stability, it is widely used in various industries, including building materials and composites. By combining organic, inorganic, and natural fibers, carbon paper has become the primary material for sheet and tile flooring and insulation and is supplied to building material manufacturers worldwide.

Carbon PaperPaperCarbon PaperCarbon paper consists of carbon fibers cut to a specific length, produced through a wet-laid technique. Due to its excellent properties, such as dimensional stability, it is widely used in various industries, including building materials and composites. By combining organic, inorganic, and natural fibers, carbon paper has become the primary material for sheet and tile flooring and insulation and is supplied to building material manufacturers worldwide. -

FoamCoreFoamHankuk Carbon's polyurethane foam is a primary material for maintaining the temperature of cryogenic liquefied natural gas from external heat in carrier tanks. It is a crucial material for our LNG insulation system. We are committed to developing and producing eco-friendly insulation foam compliant with global environmental regulations. Moreover, we are continuously striving to create new foam products that lead to customer satisfaction. We have also developed and applied various types of HD foam to reinforce LNG tanks against sloshing impacts caused by using LNG fuel during sailing.

FoamCoreFoamHankuk Carbon's polyurethane foam is a primary material for maintaining the temperature of cryogenic liquefied natural gas from external heat in carrier tanks. It is a crucial material for our LNG insulation system. We are committed to developing and producing eco-friendly insulation foam compliant with global environmental regulations. Moreover, we are continuously striving to create new foam products that lead to customer satisfaction. We have also developed and applied various types of HD foam to reinforce LNG tanks against sloshing impacts caused by using LNG fuel during sailing. -

Aramid Honeycomb CoreCoreAramid Honeycomb CoreAramid honeycomb core is manufactured by coating Nomex® paper sheets with phenolic resin. It is made from aramid paper and has a distinctive hexagonal cell shape with lightweight, strong, and non-metallic features, making it an ideal choice for high-performance aerospace components. Due to its excellent strength-to-weight ratio, it is a perfect core material for sandwich structures that use high-performance fiber-reinforced composites. Aramid honeycomb core also boasts good long-term stability and high mechanical properties.

Aramid Honeycomb CoreCoreAramid Honeycomb CoreAramid honeycomb core is manufactured by coating Nomex® paper sheets with phenolic resin. It is made from aramid paper and has a distinctive hexagonal cell shape with lightweight, strong, and non-metallic features, making it an ideal choice for high-performance aerospace components. Due to its excellent strength-to-weight ratio, it is a perfect core material for sandwich structures that use high-performance fiber-reinforced composites. Aramid honeycomb core also boasts good long-term stability and high mechanical properties. -

Battery Case Lower PanelSMCBattery Case Lower PanelSMC (Sheet Molding Compound) is a composite material that consists of unsaturated polyester or vinyl ester resin impregnated with fiberglass in the form of either fabric or chopped. It is highly cost-effective commonly used in traditional industries such as construction (for ceiling panels and water tanks) and automotive (for bumpers and truck beds). Recently, it has also been applied in battery case panels for electric vehicles.

Battery Case Lower PanelSMCBattery Case Lower PanelSMC (Sheet Molding Compound) is a composite material that consists of unsaturated polyester or vinyl ester resin impregnated with fiberglass in the form of either fabric or chopped. It is highly cost-effective commonly used in traditional industries such as construction (for ceiling panels and water tanks) and automotive (for bumpers and truck beds). Recently, it has also been applied in battery case panels for electric vehicles. -

Dry FilmFilmDry FilmHankuk Carbon has been processing and selling photosensitive dry films since 1999 in partnership with Asahi-Kasei E-Materials. Dry film resist is pasted onto copper-clad laminate and undergoes a process of UV light injection to form circuits within electronic products. It is an essential material for manufacturing Printed Circuit Boards (PCBs.)

Dry FilmFilmDry FilmHankuk Carbon has been processing and selling photosensitive dry films since 1999 in partnership with Asahi-Kasei E-Materials. Dry film resist is pasted onto copper-clad laminate and undergoes a process of UV light injection to form circuits within electronic products. It is an essential material for manufacturing Printed Circuit Boards (PCBs.)

We acquire raw materials (master rolls), which we process and supply to domestic PCB manufacturers for general PCBs and semiconductor packaging. -

Adhesive FilmFilmAdhesive FilmBondex® 750 is a structural adhesive film made of an epoxy resin and polyester carrier. It is cured at 250℉ (121℃), perfect for high-performance composite structures.

Adhesive FilmFilmAdhesive FilmBondex® 750 is a structural adhesive film made of an epoxy resin and polyester carrier. It is cured at 250℉ (121℃), perfect for high-performance composite structures. -

RSB™Multi Layer sheetRSB™RSB is Hankuk Carbon's specialized product designed to serve as the secondary barrier of the GTT Mark System. This material is of utmost importance as it protects against hull damage that may result from leakage of LNG from the primary barrier. Our innovative composites technology has enabled us to successfully localize the FSB, which is now supplied exclusively to IP manufacturers.

RSB™Multi Layer sheetRSB™RSB is Hankuk Carbon's specialized product designed to serve as the secondary barrier of the GTT Mark System. This material is of utmost importance as it protects against hull damage that may result from leakage of LNG from the primary barrier. Our innovative composites technology has enabled us to successfully localize the FSB, which is now supplied exclusively to IP manufacturers. -

FSBㆍNew FSB™Multi Layer sheetFSBㆍNew FSB™FSB is Hankuk Carbon's specialized product designed to serve as the secondary barrier of the GTT Mark System. This material is of utmost importance as it protects against hull damage that may result from leakage of LNG from the primary barrier. Our innovative composites technology has enabled us to successfully localize the FSB, which is now supplied to various shipyards and IP production.

FSBㆍNew FSB™Multi Layer sheetFSBㆍNew FSB™FSB is Hankuk Carbon's specialized product designed to serve as the secondary barrier of the GTT Mark System. This material is of utmost importance as it protects against hull damage that may result from leakage of LNG from the primary barrier. Our innovative composites technology has enabled us to successfully localize the FSB, which is now supplied to various shipyards and IP production. -

AOP™Multi Layer sheetAOP™AOP (Aluminum Opti-Insulate Paper) is a structural material made by combining organic and inorganic fibers, glass fabric, and aluminum foil. Due to its dimensional stability, it is highly specialized as a finishing material for architecture, contributing to the semi-combustible performance of interior and exterior insulation material. The smoothness and flexibility of this product have made it a popular choice across several industries.

AOP™Multi Layer sheetAOP™AOP (Aluminum Opti-Insulate Paper) is a structural material made by combining organic and inorganic fibers, glass fabric, and aluminum foil. Due to its dimensional stability, it is highly specialized as a finishing material for architecture, contributing to the semi-combustible performance of interior and exterior insulation material. The smoothness and flexibility of this product have made it a popular choice across several industries. -

AAF™Multi Layer sheetAAF™AAF (Attached Finishing with Aluminum Foil) consists of a composite film fused onto an aluminum foil and a continuous glass fiber backing fabric at high temperatures. This material is widely used as a surface material for various insulation materials, including mineral wool and glass wool. As a result of its fire retardancy and thermal resistance, it is particularly suitable for applications such as finishing insulation materials for industrial use, heat preservation ducts, and ship interiors. AAF is also used when producing glass tapes and in various fields, including construction and automotive.

AAF™Multi Layer sheetAAF™AAF (Attached Finishing with Aluminum Foil) consists of a composite film fused onto an aluminum foil and a continuous glass fiber backing fabric at high temperatures. This material is widely used as a surface material for various insulation materials, including mineral wool and glass wool. As a result of its fire retardancy and thermal resistance, it is particularly suitable for applications such as finishing insulation materials for industrial use, heat preservation ducts, and ship interiors. AAF is also used when producing glass tapes and in various fields, including construction and automotive. -

Thermoplastic PrepregRecycle & UpcycleThermoplastic PrepregThis carbon fiber prepreg utilizes thermoplastic resin liquid at room temperature. This material offers a distinct advantage in that it can be pre-impregnated at room temperature, and it is polymerized from a monomer that reacts quickly even at low temperatures, so it doesn't require expensive manufacturing devices.

Thermoplastic PrepregRecycle & UpcycleThermoplastic PrepregThis carbon fiber prepreg utilizes thermoplastic resin liquid at room temperature. This material offers a distinct advantage in that it can be pre-impregnated at room temperature, and it is polymerized from a monomer that reacts quickly even at low temperatures, so it doesn't require expensive manufacturing devices.

This material stands apart from most thermoplastic resin prepregs because of its high mechanical strength, comparable to epoxy resin, while simultaneously retaining the advantages of thermoplastic resins, such as recyclability, reshapable characteristics through thermal deformation, and ease of storage. -

Carbon PlatePlateCarbon PlateCarbon fiber plate (CFRP) is a high-tech material made by coating, heating, and pressurizing epoxy resin on carbon fiber woven fabric, which is 1/4 lighter than steel but more than ten times higher in strength and seven times higher in elasticity. It is manufactured through a one-stop production from fabric weaving, coating (prepreg), and molding, supplied to various customers and applications with excellent quality.

Carbon PlatePlateCarbon PlateCarbon fiber plate (CFRP) is a high-tech material made by coating, heating, and pressurizing epoxy resin on carbon fiber woven fabric, which is 1/4 lighter than steel but more than ten times higher in strength and seven times higher in elasticity. It is manufactured through a one-stop production from fabric weaving, coating (prepreg), and molding, supplied to various customers and applications with excellent quality. -

Glass PlatePlateGlass PlateGlass fiber plate (GFRP) is a high-tech material made by coating continuous glass fiber fabric with epoxy resin and then heating and pressurizing it. It has excellent mechanical strength and, above all, superior electrical properties. It is manufactured through a one-stop production from fabric weaving, coating (prepreg), and molding, supplied to various customers and applications with excellent quality.

Glass PlatePlateGlass PlateGlass fiber plate (GFRP) is a high-tech material made by coating continuous glass fiber fabric with epoxy resin and then heating and pressurizing it. It has excellent mechanical strength and, above all, superior electrical properties. It is manufactured through a one-stop production from fabric weaving, coating (prepreg), and molding, supplied to various customers and applications with excellent quality. -

Pultruded CFRPPlatePultruded CFRPPultruded CFRP is used to reinforce the cross-sections of bridges or ferroconcrete structures that lack structural strength. It improves strength, durability, seismic performance, and corrosion resistance. Its lightweight quality reduces the structural load of the building and has better construction ability than steel plate and H-beam reinforcement methods.

Pultruded CFRPPlatePultruded CFRPPultruded CFRP is used to reinforce the cross-sections of bridges or ferroconcrete structures that lack structural strength. It improves strength, durability, seismic performance, and corrosion resistance. Its lightweight quality reduces the structural load of the building and has better construction ability than steel plate and H-beam reinforcement methods. -

Composites, All at once.ServiceServiceOur One-Stop Solution offers a comprehensive service from manufacturing materials to prototypes.

Composites, All at once.ServiceServiceOur One-Stop Solution offers a comprehensive service from manufacturing materials to prototypes.