[Composite Materials 101] Prepreg, a High-performance Composite Material

<p><img alt="" src="https://www.hcarbon.com/upload/ckeditor/8c96d069-9102-4178-8498-17e9a3d5905e.jpg" style="width: 70%;" /></p>

<p> </p>

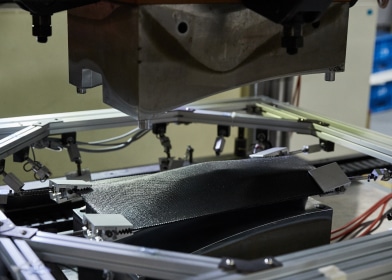

<p>Composite materials play a vital role in the high-tech industry, where there is a demand for lighter and stronger materials. What is a prepreg? Prepreg is a high-performance composite used in various applications, ranging from sports and leisure equipment, like tennis rackets, golf clubs, bicycles, and hockey sticks, to advanced components in industries such as future mobility, automobiles, and aircraft.</p>

<p><br />

Prepreg is a commonly used composite material, but its concept may be unfamiliar to some. In this episode, we will explore the definition of prepreg, its strengths, and the manufacturing methods with Hankuk Carbon, a leading company in the intermediate material sector.</p>

<p> </p>

<p> </p>

<p><span style="font-size:20px;"><strong>What is a Prepreg?</strong></span></p>

<p><br />

A prepreg is an intermediate product used in the fabrication of high-tech components. The term "prepreg" comes from "pre-impregnated material," which refers to <strong>a material created by impregnating resin into reinforcing fibers, such as carbon fiber, glass fiber, or aramid fiber.</strong><br />

The resin used in the composite material remains in a liquid state at room temperature. It changes into a solid state when heat and pressure are applied with a curing agent. Curing refers to the process that hardens the material, allowing the prepreg to be transformed into a lightweight, high-strength component through the curing process of the resin.</p>

<p><br />

Prepreg is characterized by its <strong>"semi-hardened"</strong> state. This semi-hardening stage occurs before the material is fully cured, which happens when heat and pressure are applied. Prepreg is a sheet-type material consisting of fibers pre-coated with resin, allowing it to be easily cut into desired shapes and formed before being cured. This process enables convenient and efficient manufacturing of high-tech parts. Unlike traditional manual methods, prepreg maintains a consistent ratio of fiber to resin, which enhances quality and significantly reduces manufacturing time, contributing to the advancement of various industries.</p>

<p> </p>

<p> </p>

<p><br />

<span style="font-size:20px;"><strong>High-tech Products Completed through Curing of Resin</strong></span></p>

<p> </p>

<p><img alt="" src="https://www.hcarbon.com/upload/ckeditor/e3c9d18b-bb0a-448b-99f0-cea8a91e8e23.jpg" style="width: 70%;" /></p>

<p><br />

Resin is essential for prepregs. Although carbon fiber is gaining attention as an advanced material, it is valuable as a composite only if combined with resin.</p>

<p><br />

Carbon fibers provide strength and elasticity in carbon fiber prepreg materials, while the resin acts as an adhesive to bond the fibers together, forming the final part. The resins used in composite materials are primarily categorized into two types: thermosetting resins, such as epoxy and phenolic, and thermoplastic resins, like polyester. Once thermosetting resins are cured, they undergo an irreversible process, meaning they cannot be reshaped. In contrast, thermoplastic resins can change their shape even after curing. Most carbon fiber composite materials utilize thermosetting resins.</p>

<p><br />

The prepregs are arranged and stacked in a pre-designed mold to shape them. They are then cured into the final product by applying heat and pressure in various ways. After curing, the prepregs are transformed into composite materials, such as CFRP (Carbon Fiber Reinforced Plastic), which uses carbon fibers, and GFRP (Glass Fiber Reinforced Plastic), which uses glass fibers.</p>

<p> </p>

<p> </p>

<p><span style="font-size:20px;"><strong>Hankuk Carbon's Various Resin Systems</strong></span></p>

<p><br />

Hankuk Carbon offers a variety of resin systems tailored for different applications and environments. One of our standout products is the fast-cure resin system, the FC-Series, which cures in approximately four minutes. This rapid curing time makes it ideal for mass production, as more parts can be produced in the same amount of time. The FC 9-Series possesses flame-retardant properties and is specifically designed for battery cases, an essential component of eco-friendly electric vehicles (EVs).</p>

<p><br />

Furthermore, Hankuk Carbon developed a biomass-based resin system for eco-friendly industries. Among the FC-Series, FC-1310 has been certified as a bioplastic in Korea, containing over 25% biomass. This resin offers the advantage of reducing carbon emissions without compromising on quality, compared to traditional composite materials that use existing epoxy resins.</p>

<p> </p>

<p><br />

Prepreg, a high-performance composite material, is gaining attention as a future material in various industries. Hankuk Carbon's advanced resin systems and prepreg manufacturing technology offer innovative solutions for fields that require lightweight yet high-strength materials, contributing to sustainable development. See you in the next story with more valuable insights about composite materials!</p>

- Composites

- Prepreg

- Resin

- Mobility

- Auto

- Air

- Sports & Leisure

- Sustainability

See More

PCM

PCM Autoclave

Autoclave Oven

Oven