Rail

-

Our structured part production

9,030㎡

site in Korea -

Production

11,000㎡

site in Vietnam

Key Technologies

Technology-

Major manufacturing facilities (Korea)

Major manufacturing facilities (Korea)- Large-sized, middle-sized ovens and four painting booths available, essential for composites production

- Able to produce large components, including cap masks for high-speed trains

- Medium-sized painting booth is under humidity control and has been certified by IAI

-

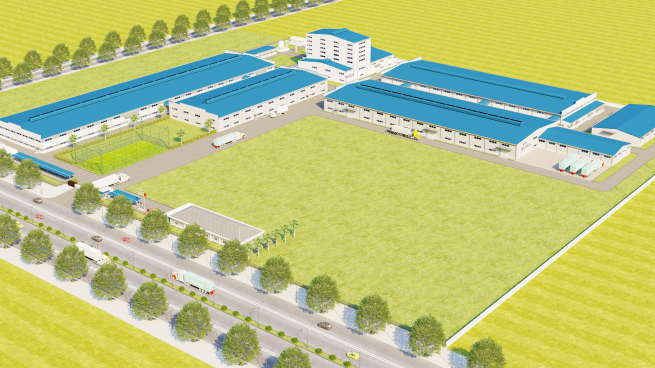

Major manufacturing facilities (Vietnam)

Major manufacturing facilities (Vietnam)- Ready to produce from materials to components

- Maximization of Vietnam production to achieve cost competitiveness in the rail industry

-

Railway Vehicle One-Stop Solution: from Components to Modules

Railway Vehicle One-Stop Solution: from Components to Modules- All composite components for railway vehicles are producible

- Various application cases such as ShinAnsan Line, Seoul Subway Line 5-8 cap modules, etc.

-

Technology and Performance at a Global Market Level

Technology and Performance at a Global Market Level- Provides innovative solution for railway vehicles with excellent strength and durability

- Meets the highest level (level 4) of fire-retardancy based on domestic rail vehicle standards

- Meets the highest level (HL3) of fire-retardancy based on the European fire safety test, EN45545-2 R1

- Facilities certified by Boeing Material Specification (BMS) certification to ensure they meet international standards

- First Korean composites manufacturer to receive ISO/TS 22163:2017 certification for railway quality management system (Vietnam plant additionally certified in 2023)

Contact Us

Introducing Hankuk Carbon's One-Stop Solution

- a comprehensive composite solution

from raw materials to product application.